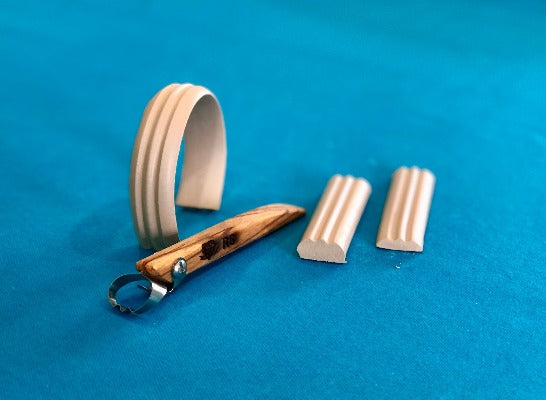

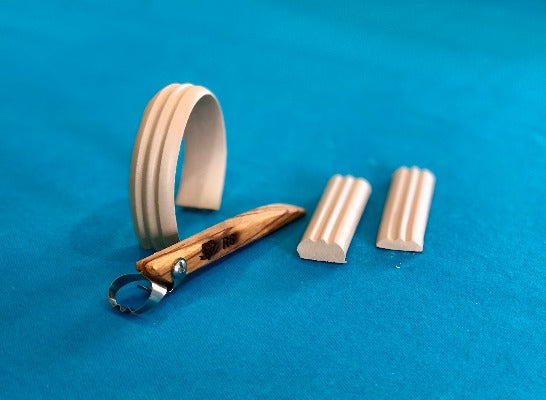

The super-sharp blades on the R8 Double Line Handheld Clay Extruder are engineered to pull through a slab of clay to make a handle shape with double lines down the middle. Create handles for slab-built platters and dishes with ease.

DESCRIPTION

- Slices through a slab to make a strip with double lines down the middle

- Angled, stainless-steel blade leaves clean edges and pulls through clay effortlessly

- 4 3/8-inch (11 cm)-long hardwood handle

- Great for feet, handles, and more

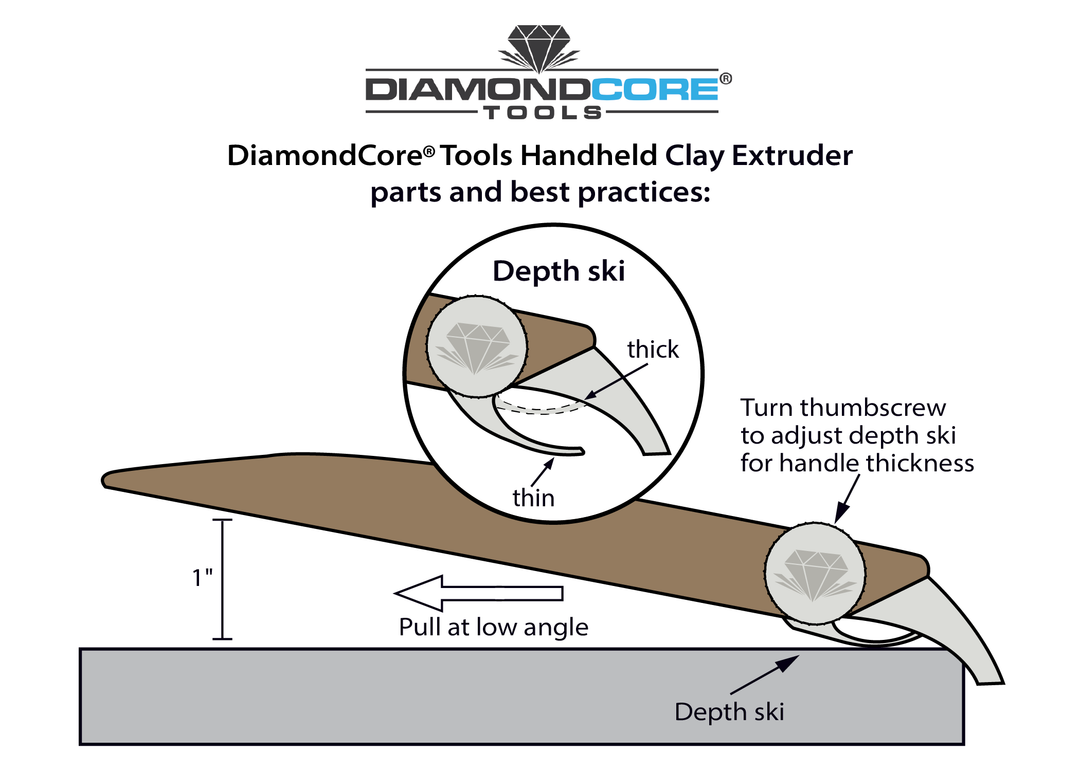

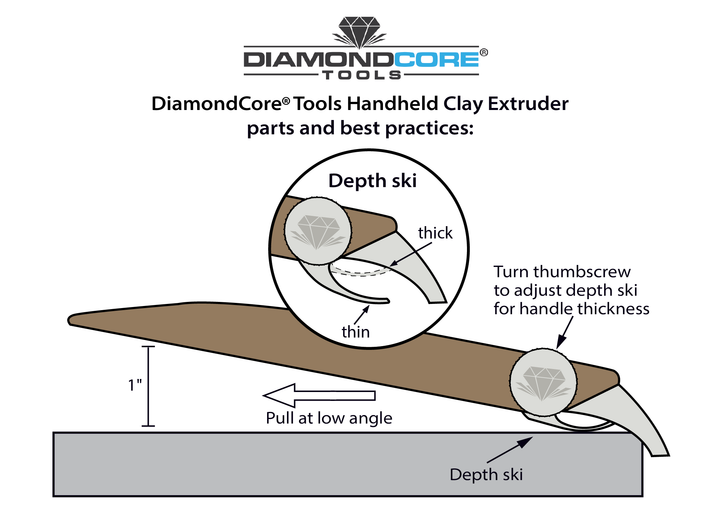

- Adjustable-depth ski controls the thickness of the cut

- The thumb screw allows for easy ski adjustment

- Max approx. blade width 21mm X height 15 mm

- Min approx. blade width 20 mm X height 9 mm

- Wood grain may vary

USES/BENEFITS

- Make feet for slab-built pieces

- Ideal for hand-builders and useful for throwers

- Consistent shape and adjustable thickness

- So easy to use; avoid all that pulling

- Works on a variety of clay types

- Always-sharp stainless-steel blade won’t rust or shatter

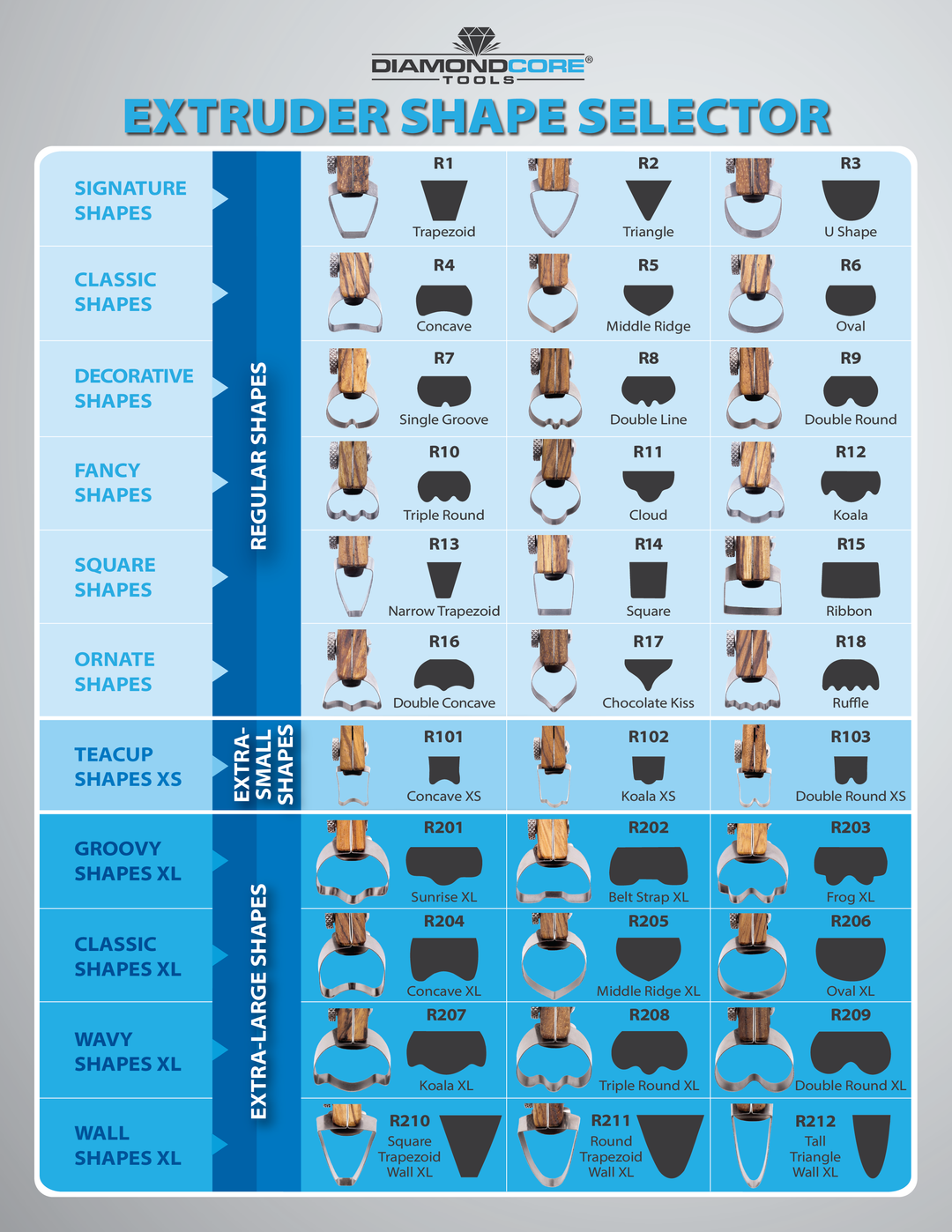

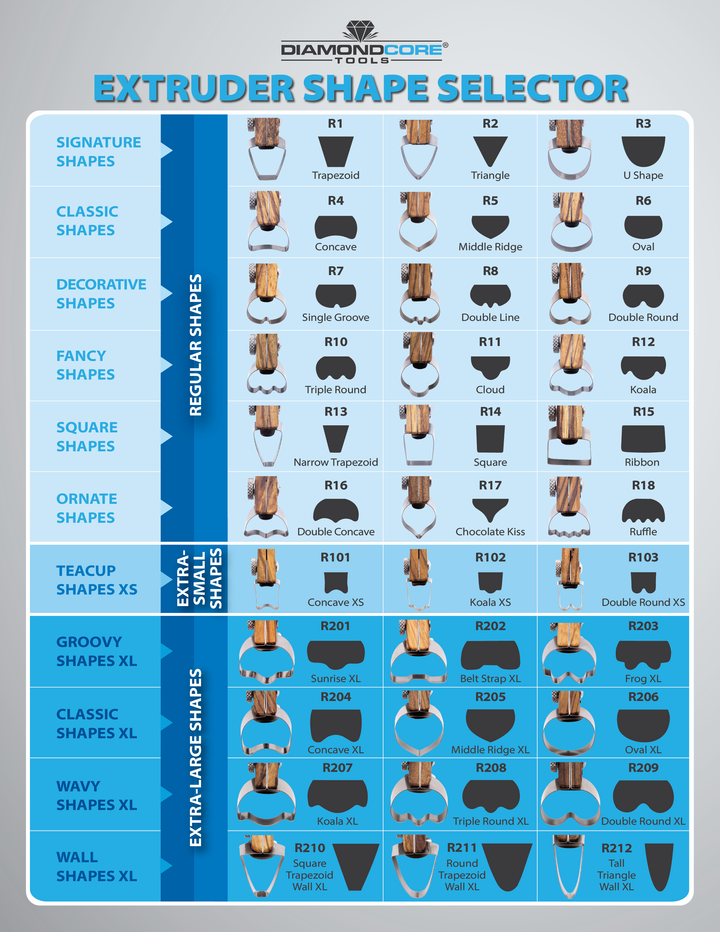

- A variety of basic and intricate shapes are available

CAUTIONS

- Not designed to be used with extremely wet or sticky clay

- Use all safety precautions

- Keep out of the reach of children

TIP

For best results, use these foot and handle-making tools when the clay is not extremely wet or sticky. The clay tool blade should be clean and dry. Ideally, pull the extrusion up and out as it is being formed or fold back the sides of the slab so the extrusion pops up and out.

Recently viewed